WELDING PROCESS

Software solutions for efficient welding process control

The harmonized normative regulations – “Euro-norms” – have acted as a big bang in the established welding system in manufacturing companies. In order to maintain professional certifications it is essential to meet all requirements of legislative and normative regulations. We have done the grunt work for you and found out what each standard actually contains.

WELDING PROCESS

Software solutions for efficient welding process control

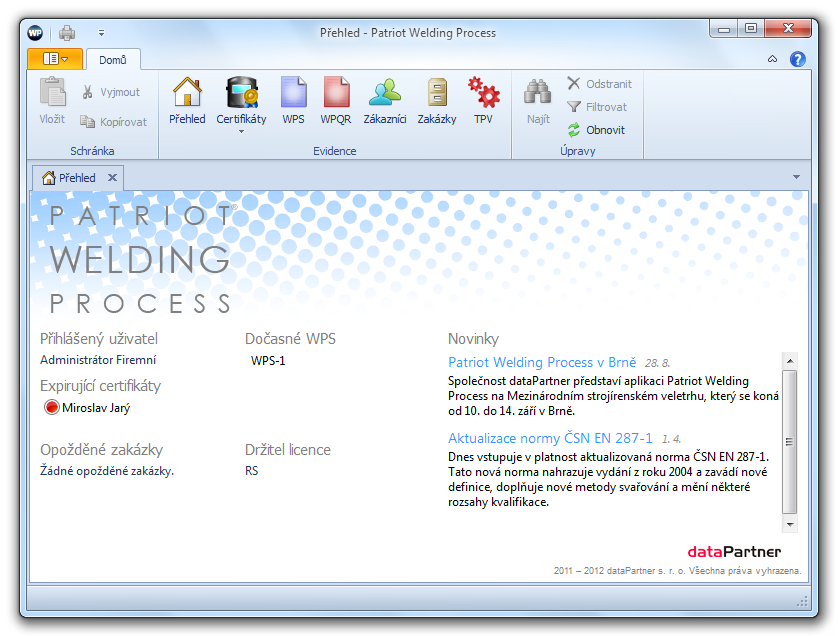

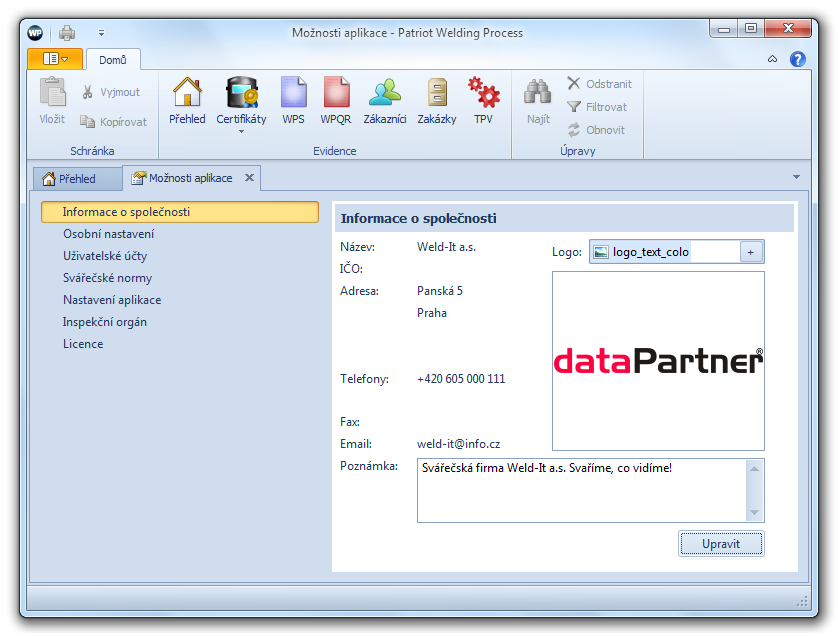

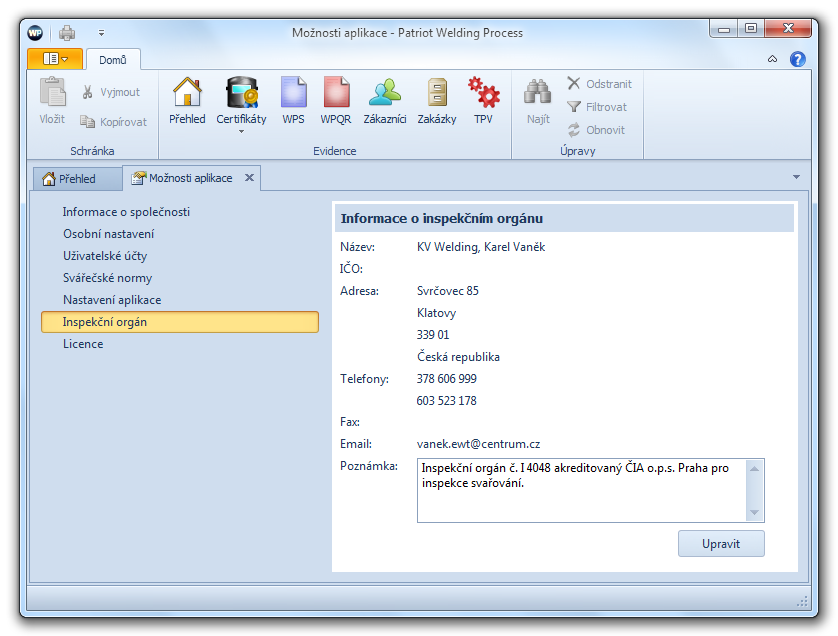

The Patriot Welding Process application simplifies the production management for individual orders (product documentation, standards, materials, procedures, etc.), helps in filling out forms (inspection plan, quality plan, initial type test, weld production test, CE declaration, declaration of conformity), management of technological production procedures (records of product parts, welds, selection of a qualified welder, selection of WPS, determining the percentage of welds for additional inspection). It manages the database of welders and data in regards to their qualifications. Records WPQR, WPS – including facilitating its establishment, includes printouts for individual documents and forms. Significantly facilitates the creation of production guides in the scope of the purchased edition of the program and furthermore allows automatic generation of draft controls.

The program has a number of additional features that help manage the demanding administrative work and ensure the welding process records all data and meet regulatory requirements that are complete, accurate, auditable and controllable.

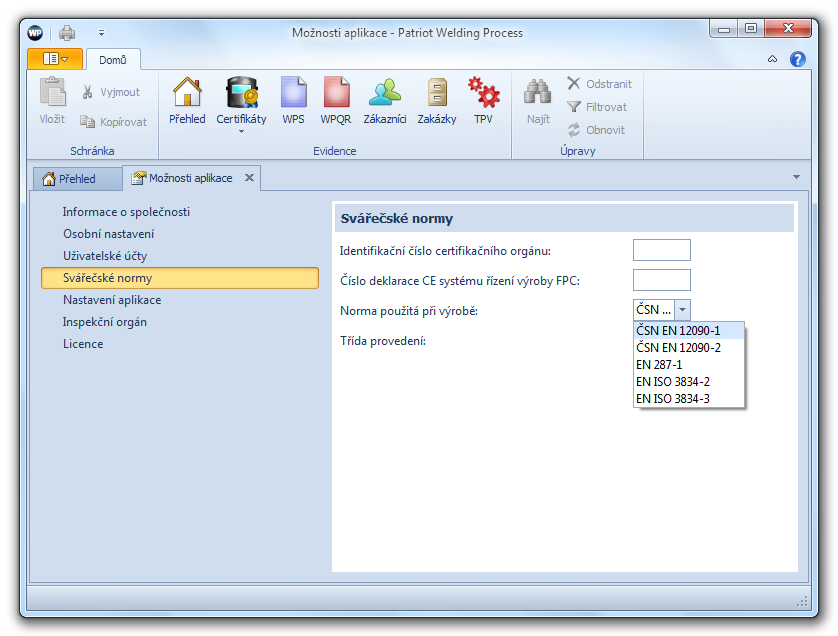

The system has been developed on the basis of the obligations arising in particular from the following legislation: Act No. 22/1997 Coll., NV No. 190/2002 Coll., as amended by NV No. 251/2003 Coll, No 128/2004 Coll. (89/106/EEC), ČSN EN 1090 – 1 to 3, ČSN EN ISO 3834, ČSN EN ISO 15 607, ČSN EN ISO 15 609-1, ČSN EN ISO 15 614-1, ČSN EN ISO 17637, ČSN EN ISO 473, ČSN EN ISO 14731 (719), ČSN EN 287 – 1, ČSN EN 10013, ISO 383-2/34, ČSN EN ISO 15 614-1; ČSN EN ISO 17637.

Qualifications and procedures records

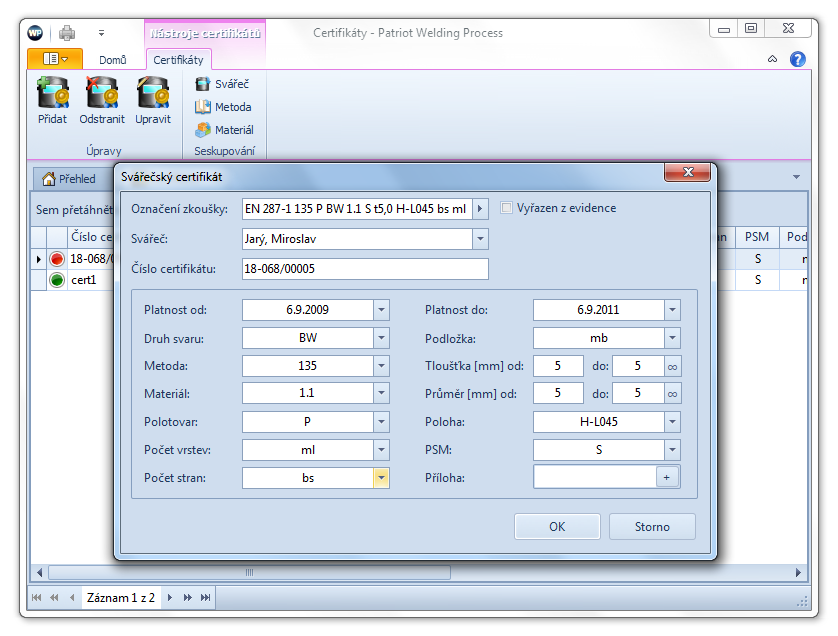

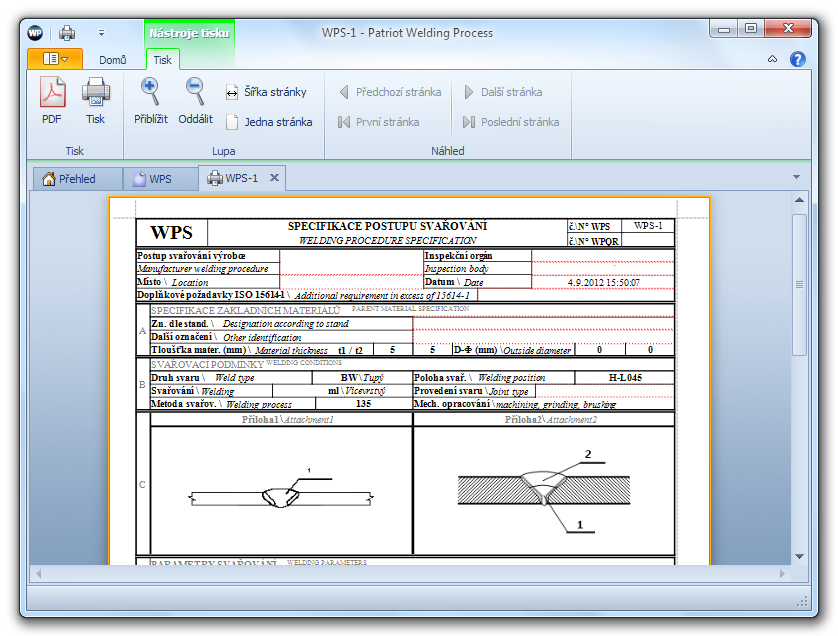

DOCUMENTATION MANAGEMENT (WPSM, WPQR)

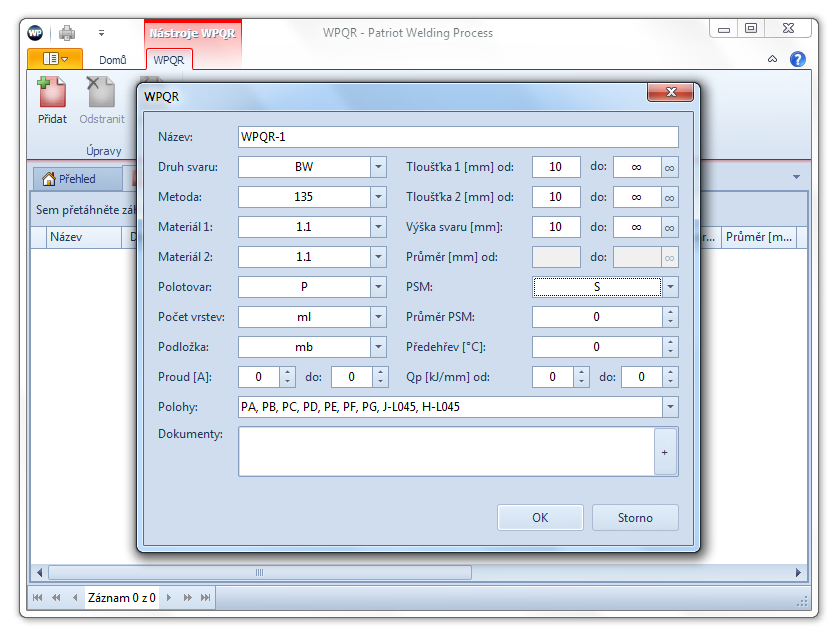

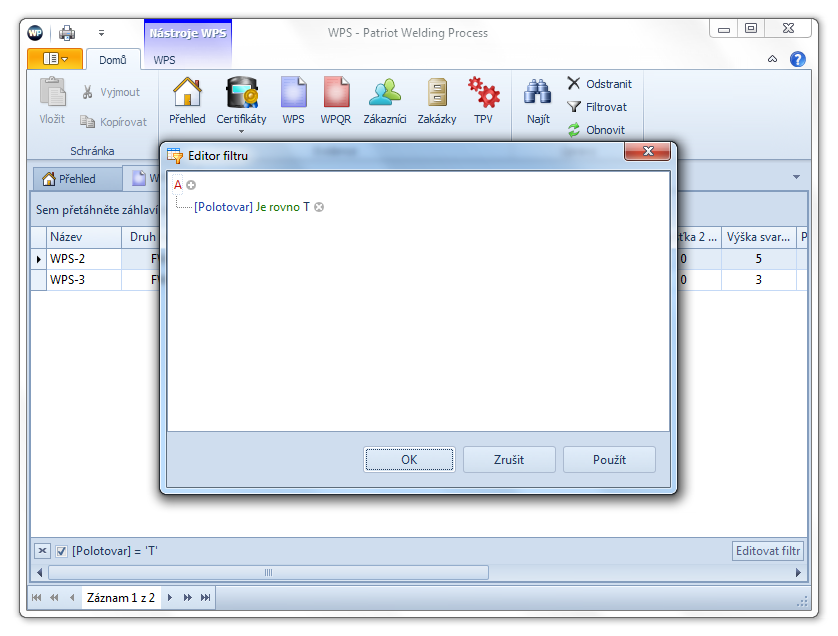

Welding procedure qualification records (WPQR) according to ČSN ISO 15614 and welding procedure specification records (WPS) according to ČSN ISO 15609 are essential documents of a properly lead welding company. The program allows the creation of a new WPS, WPQR, editing of existing items, filtering according to specified criteria and export to external formats. It is possible to create a detailed printout for each WPS.

PRE-FILLED FORMS

The forms that are required to be maintained or supplied with the order are prepared with basic pre-filled data, making their completion very simple and user-friendly. The program includes a Test Plan, Production Weld Test, CE Declaration and an EC Declaration.

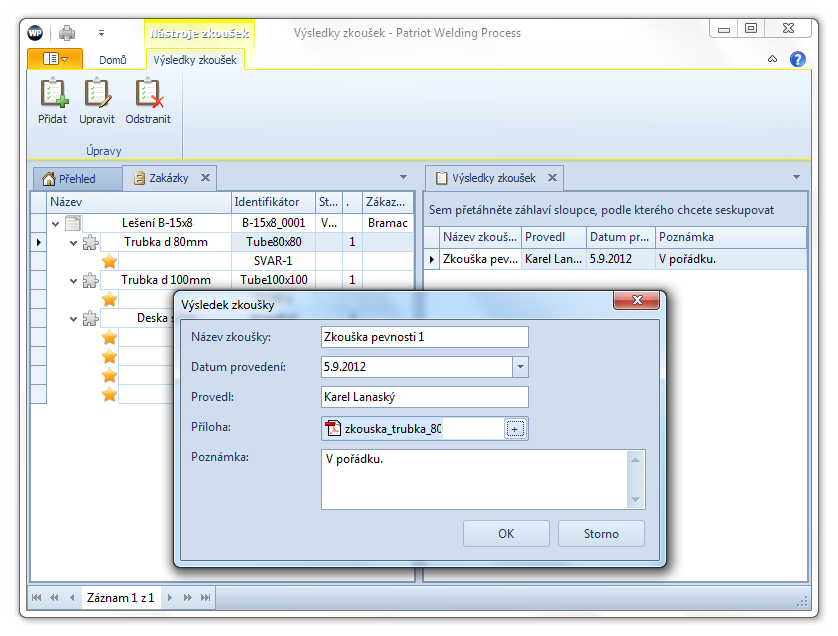

CONNECTING EXTERNAL DOCUMENTS

External documents such as photographs, drawings, certificates, official decisions, etc. can be attached to the documentation to the required extent.

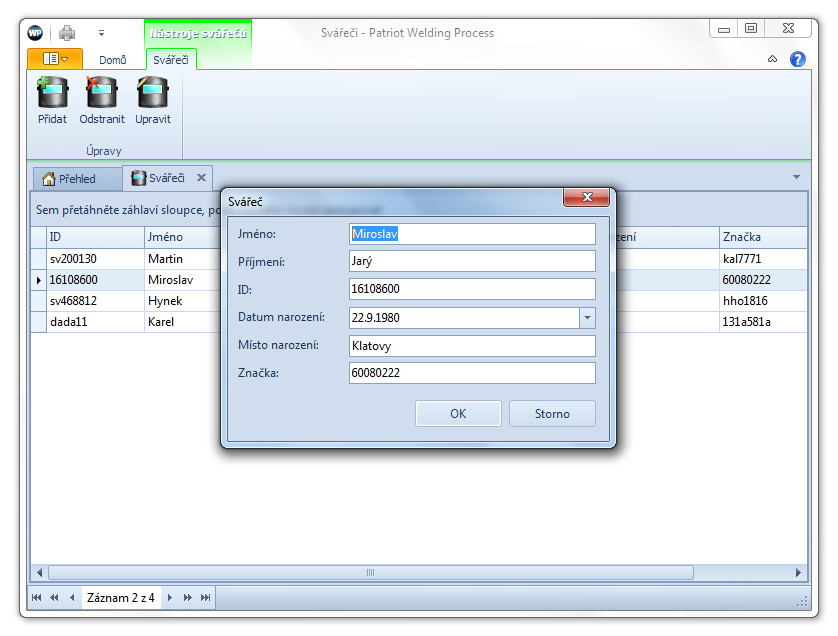

REGISTRATION OF WELDERS

The foundation is a database of welders and their certificates, including notification of the approaching expiry date of the certificate. It allows to keep the database up-to-date by editing, filtering according to the specified qualification, material, welding location, etc., exporting the database to external formats. Interfacing with other modules allows the program to offer suitable welders for the implementation of specific welds.

DOCUMENTATION MANAGEMENT (WPSM, WPQR)

Welding procedure qualification records (WPQR) according to ČSN ISO 15614 and welding procedure specification records (WPS) according to ČSN ISO 15609 are essential documents of a properly lead welding company. The program allows the creation of a new WPS, WPQR, editing of existing items, filtering according to specified criteria and export to external formats. It is possible to create a detailed printout for each WPS.

PRE-FILLED FORMS

The forms that are required to be maintained or supplied with the order are prepared with basic pre-filled data, making their completion very simple and user-friendly. The program includes a Test Plan, Production Weld Test, CE Declaration and an EC Declaration.

CONNECTING EXTERNAL DOCUMENTS

External documents such as photographs, drawings, certificates, official decisions, etc. can be attached to the documentation to the required extent.

REGISTRATION OF WELDERS

The foundation is a database of welders and their certificates, including notification of the approaching expiry date of the certificate. It allows to keep the database up-to-date by editing, filtering according to the specified qualification, material, welding location, etc., exporting the database to external formats. Interfacing with other modules allows the program to offer suitable welders for the implementation of specific welds.

Try the Patriot Welding Process app today.

Sign up and get a 30-day license key for the fully functional app for free.

Production Managemant

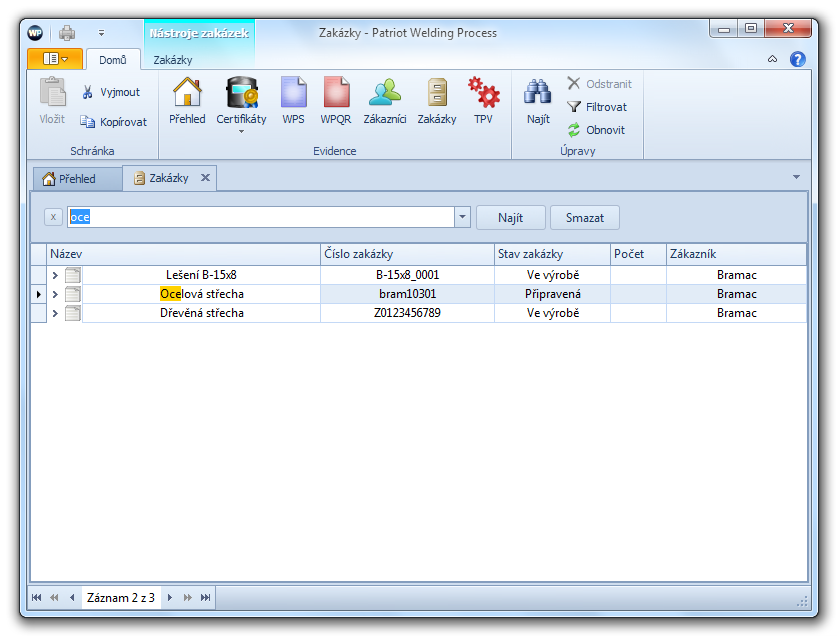

Contracts

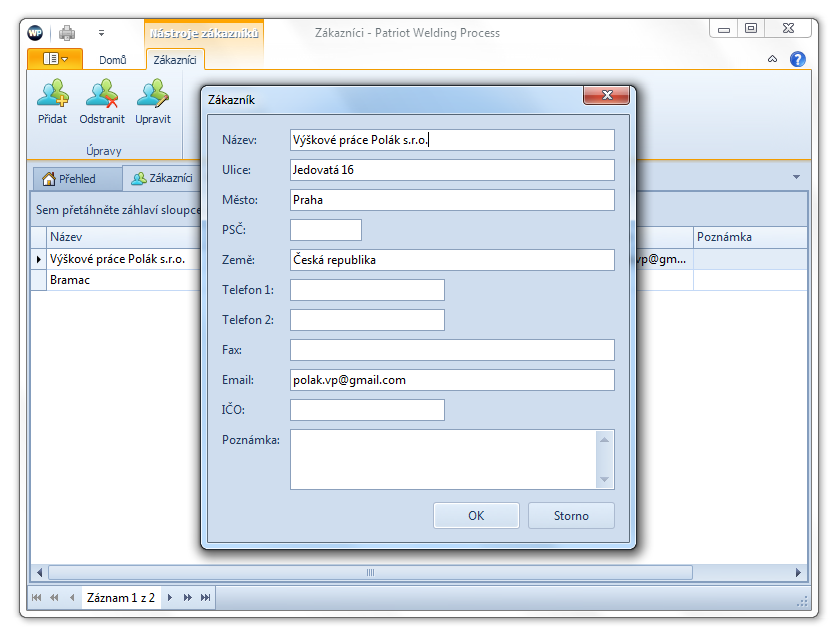

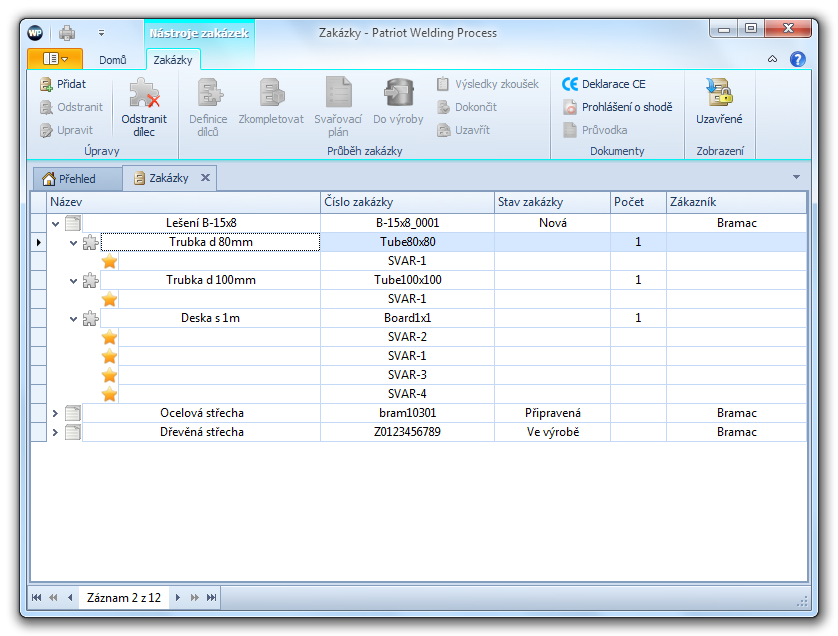

The program manages the database of orders – identification data, status, order number, EXC classification, documentation specification. The standards, materials, procedures, information about required products and their quantities, customer information, etc. are recorded. Scanned certificates of basic or additional material, welding supervision diploma, visual inspection certificate and others can be attached to the order as required by the user.

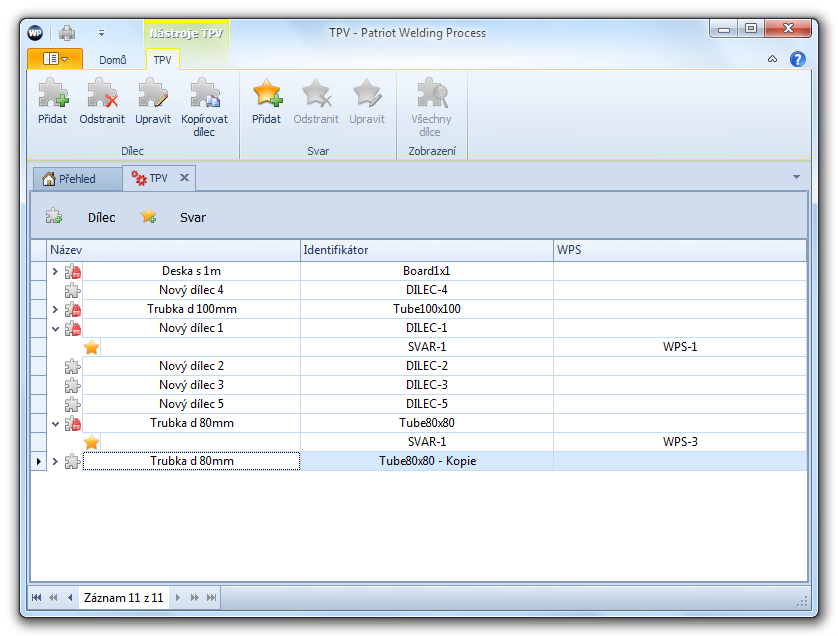

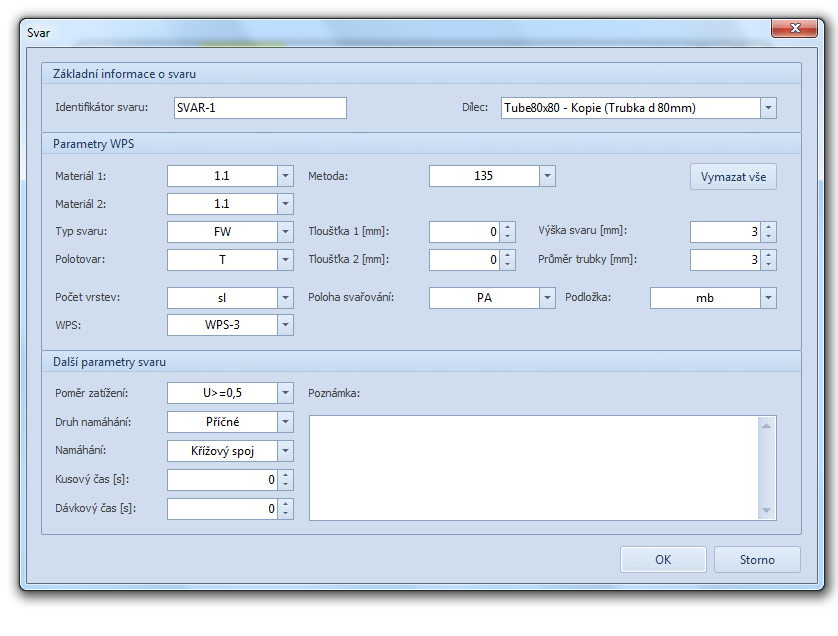

Technological procedure control

Describes which parts make up the product or which subparts make up the individual parts. For each part, a list of welds and a drawing of it is maintained. For each weld, the type, the basic and additional material used, the weld position, WPS, material thickness and other necessary data are indicated.

Production guide

Depending on the edition of the program purchased, the program facilitates the creation of the production guide either manually or automatically.

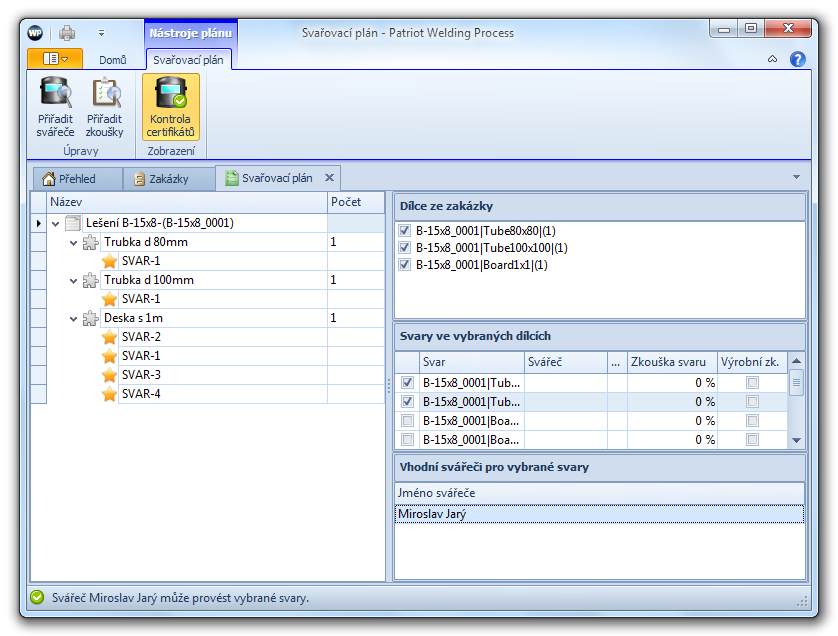

Automatic generation of production guides and design of controls: According to the specified parameters of individual welds, the software suggests the use of the most suitable welding procedure (WPS) from the available databases then selects a suitable qualified welder (can be edited manualy) and determines the required percentage of welds for additional inspection (NDT). It allows semi-automatic determination of the required weld tests and recording of weld test reports. Data on individual welds can be exported to external formats.

Manual creation of production guides: The technological process is determined by contract management database, qualification management a the management of documentation. Every weld should be carried out by a qualified welder using a adequate material and an appropriate procedure (WPS) with the right proportion of welds for additional NDT inspection. The attached form should be filled manually with all the necessary data.